The League of Smart Engineering 5.0

An ecosystem of Expert Engineers, distinct from IT Consultants, Spearheading the Evolution from Industry 4.0 to the Precision of Engineered Industry 5.0. Unleashing Innovation, Redefining Possibilities.

League of Companies

About The League of Smart Engineering

A Group of Highly skilled engineers remodeling and reshaping industry 4.0 to Engineered Industry 5.0

Overall, while IT resources can be highly skilled and valuable for many engineering projects, running smart engineering 5.0 with qualified engineers is essential for ensuring optimal results and meeting the specific requirements of complex engineering projects.

Domain

Expertise

Qualified engineers possess domain-specific knowledge and expertise that is critical for designing and developing complex systems and products. They have a deep understanding of the physical and mechanical principles that underlie the products they work on and are trained to optimize designs to meet specific performance and safety requirements. This domain knowledge is essential for effectively leveraging smart engineering 5.0 tools and methodologies.

Understanding Customer Needs

Qualified engineers have a strong understanding of customer needs and requirements and can effectively translate these needs into technical specifications. This is critical for developing products that meet customer needs and expectations and can help to ensure customer satisfaction.

Regulatory

Compliance

Many industries have strict regulations and standards that must be met in order for products to be approved for use. Qualified engineers have a deep understanding of these regulations and can design products that meet these requirements. This is essential for ensuring the safety and reliability of products, and for avoiding regulatory penalties and legal liabilities.

Effective

Collaboration

Smart engineering 5.0 involves the use of complex tools and methodologies and requires effective collaboration between different teams and stakeholders. Qualified engineers have the necessary communication and collaboration skills to work effectively with other engineers, product managers, and other stakeholders to ensure that projects are delivered on time and within budget.

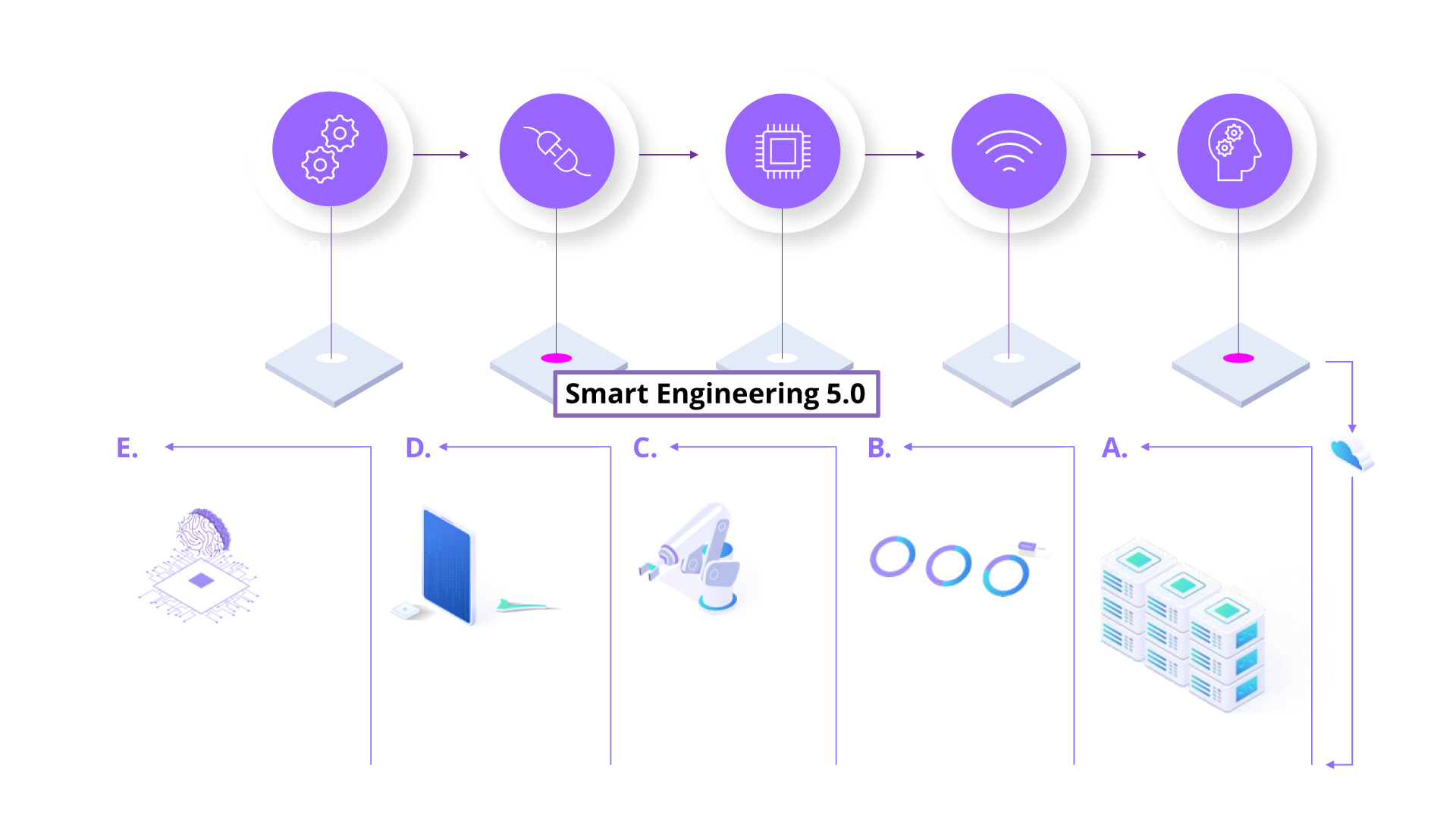

Smart Engineering 5.0 Explained

Refers to the methods, processes, and information technology tools used in the interdisciplinary, system-oriented development of creative, intelligent, and networked products, manufacturing plants, and infrastructures.

The previous Tier Industry 4.0 emerged with the same entrance of automation technologies, IoT, and the smart factory. Industry 5.0 is the next phase, which advances by using the collaboration of increasingly powerful and accurate technology and the unique creative potential of the human being.

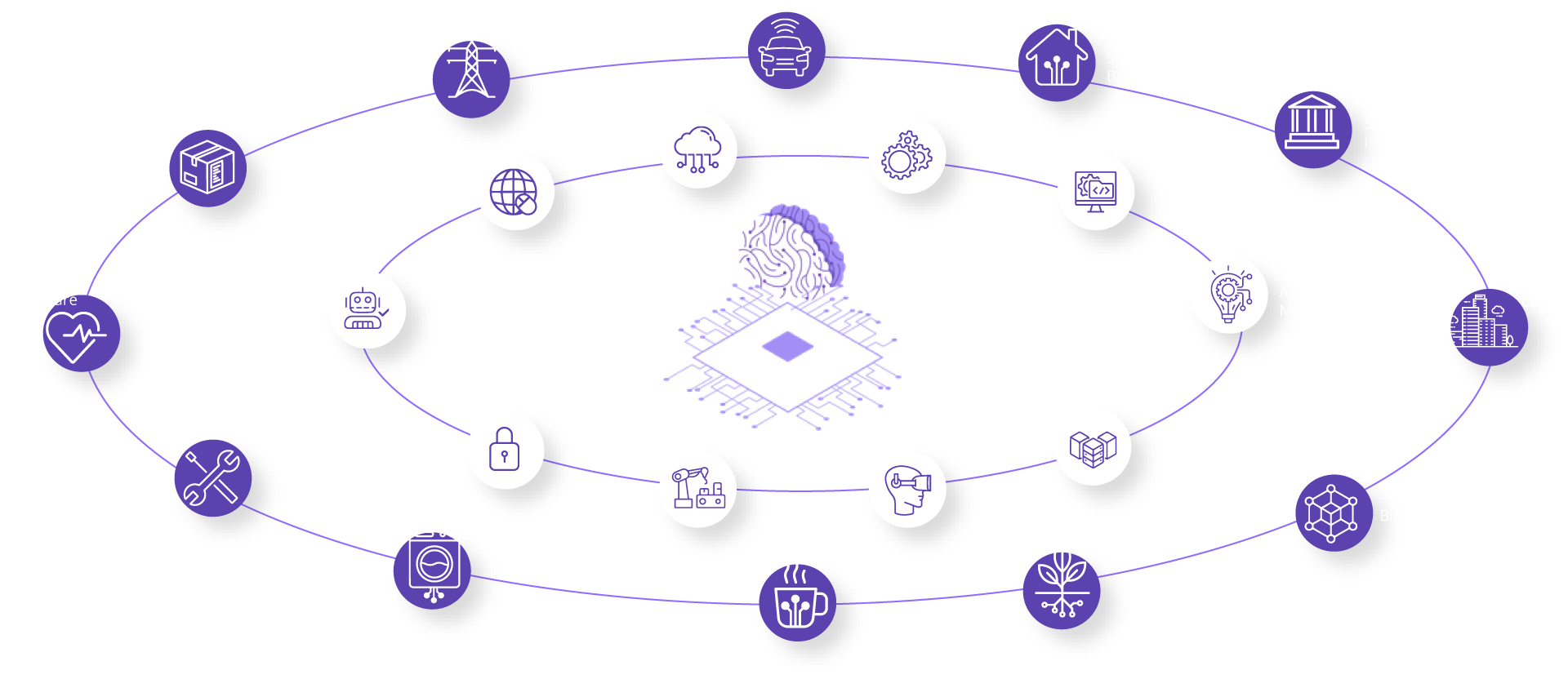

Industry 5.0

Anything Smart

League of Companies

OT Service Offerings

- Manufacturing Process & Technology

- Design Optimisation for Manufacturing

- Project & Product Planning/Engineering

- Continuous Process Improvement

- Operations: Production and Quality Management

- Prototype: Industrialisation and Production Phase Support

- Digital Manufacturing Implementation

- Manufacturing Processes & Procedures

- NC & CNC Optimisation Techniques

- Balance Hardware for Efficient Component Output

- Maximise Capacity & Moderate Consumable Cost

- Design for Manufacture

- Reduce Complex Attributes in a Part Design

- Optimise & Produce Manufacturing Documents

- Review of Components for Manufacturing Cost Reduction

- Create, Monitor and Control Project Timelines (KPI)

- Master Resource Plan

- Plan and Control Financial Budgets

- Technology Road-mapping of the entire Product

- Lean and 5S principles

- Root-Cause Analysis

- Minimise Waste and Scrap

- Efficient Use of Human and Physical Resources

- Updates of Processes and Procedures

- Implementation of Technology and Innovation

- Effective Use of Available Resources

- Create and Monitor Daily/Weekly Production Schedules

- Adherence to Processes and Procedures

- Manufacturing Training and Development

- Skill Retention and Advancement

- Standards and Accreditations

- Creation of Manufacturing Processes and Procedures

- Structuring the Facility Resources

- Creating Stability within the Environment

- Finding Positive Solutions to Root-Cause Analysis Issues

- Creating a worthy Infrastructure for Production

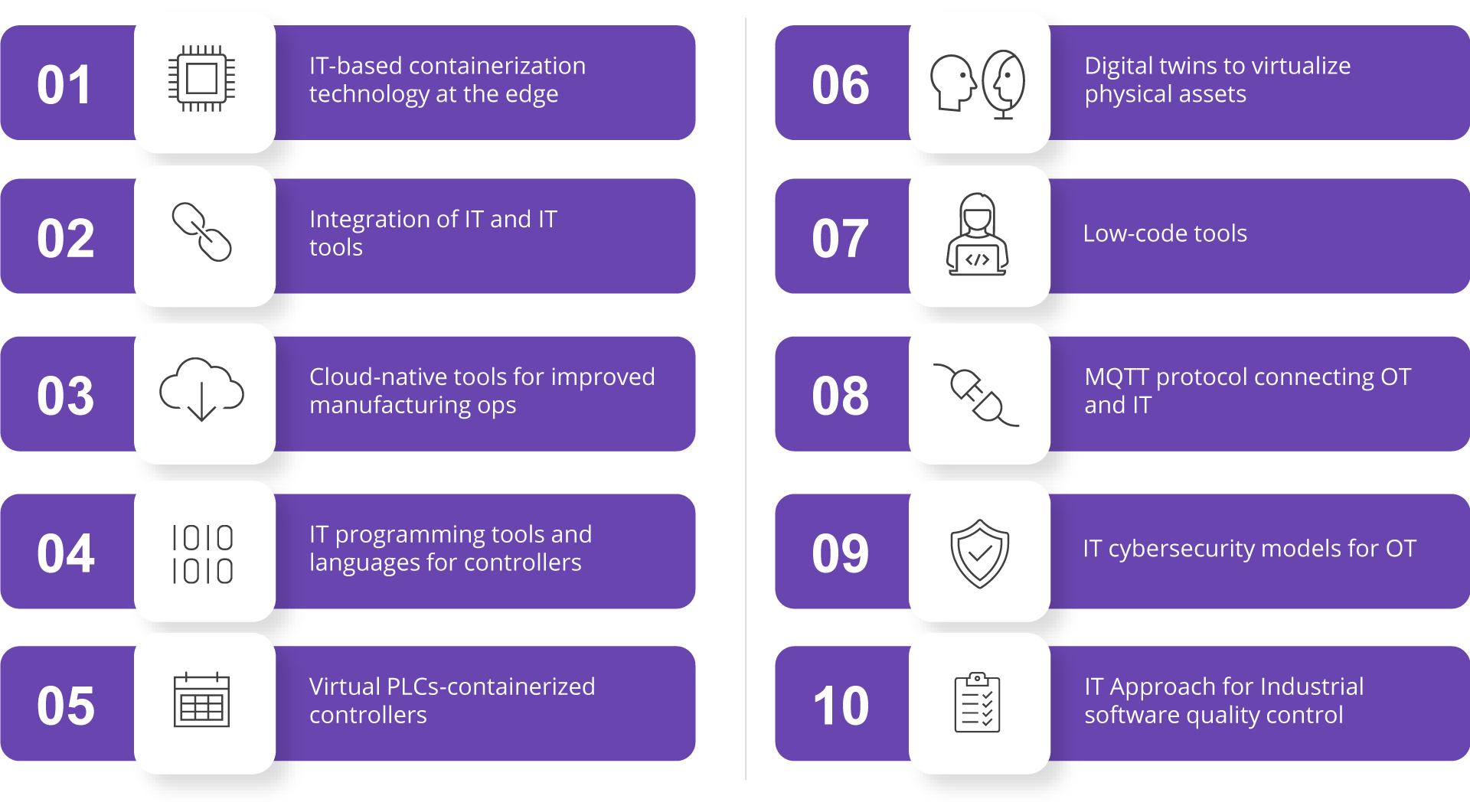

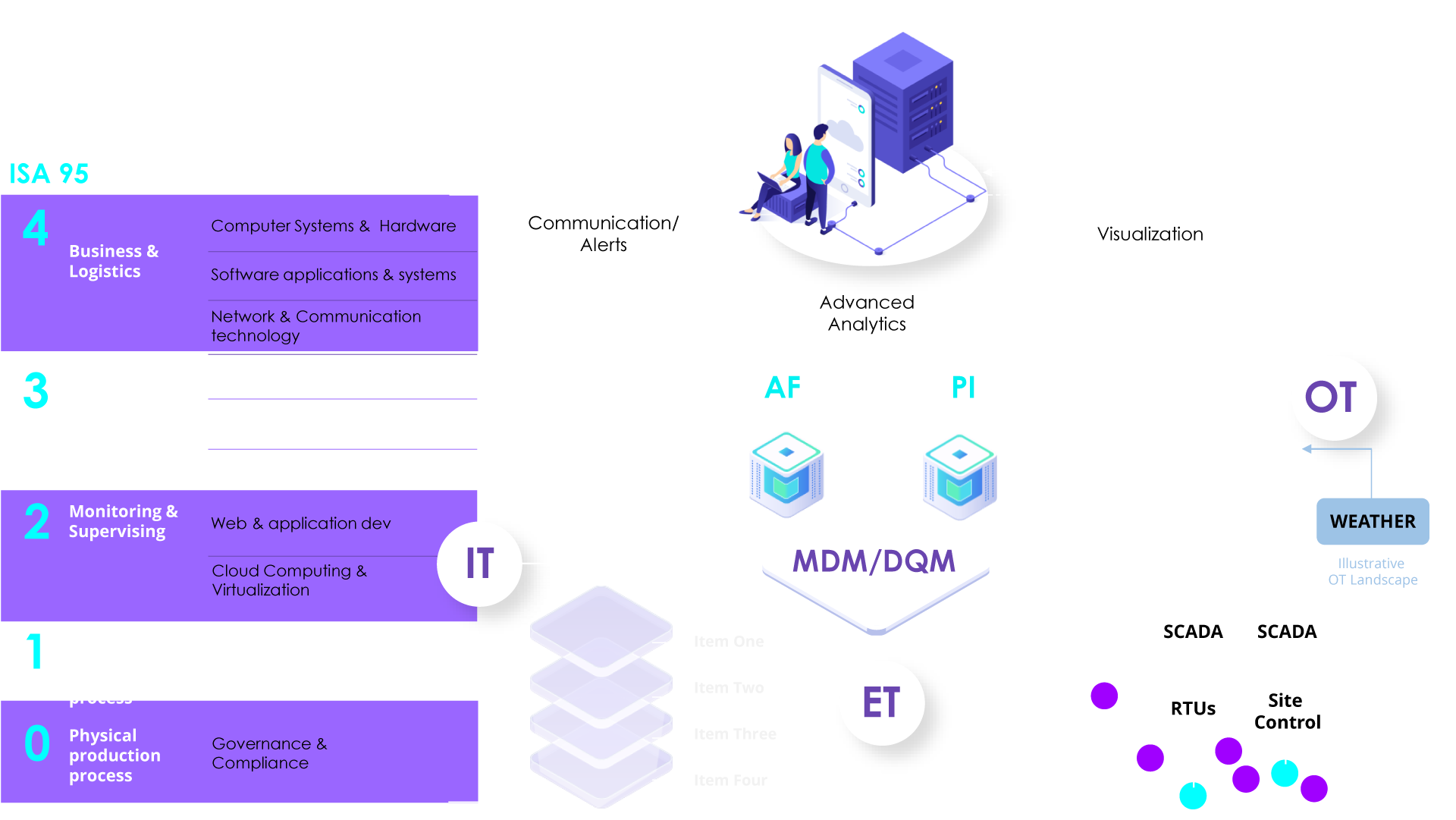

10 IT/OT Convergence Trends

League of Companies

Our Solutions Include:

- IT/OT Convergence

- Smart Manufacturing

- Smart manufacturing: Industrial Advance Analytics

- IT/OT Cyber Security

- IT/OT Data Management

League of Companies

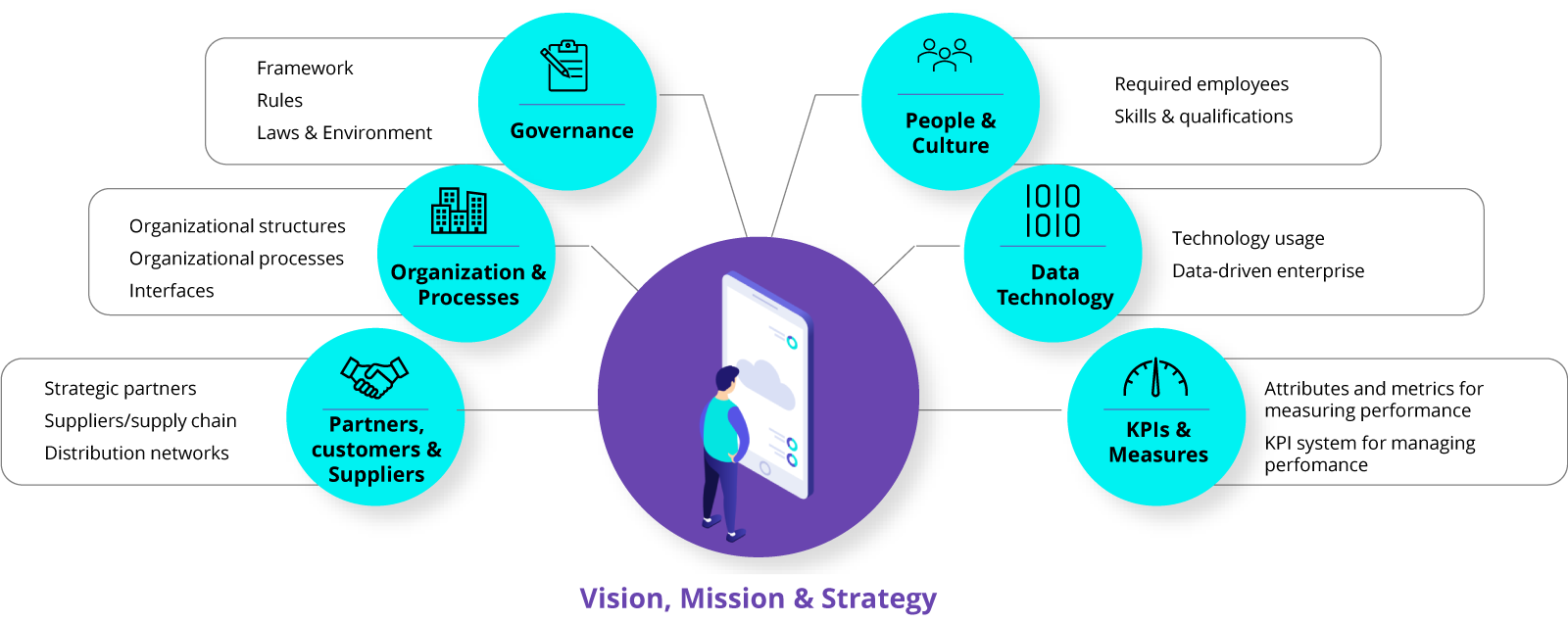

The Convergence of Information Technology (IT), Operating Technology (OT), and Engineering Technology (ET) delivers several significant business benefits to an organization.

Here are some of the main benefits:

- Enhanced Operational Efficiency

- Improved Decision-Making and Agility

- Enhanced Collaboration and Communication

- Cost Reduction and Resource Optimization

- Improved Safety, Security, and Compliance

- Accelerated Innovation and Digital Transformation

- IT-OT-ET convergence streamlines and optimizes operational processes, reducing manual efforts and improving overall efficiency.

- Automation and integration of systems enable smoother workflows, faster data exchange, and more streamlined decision-making processes.

- Real-time data visibility and analytics empower organizations to identify bottlenecks, optimize resource allocation, and improve operational performance.

- Convergence enables organizations to access comprehensive and real-time data from IT, OT, and ET systems, providing a holistic view of operations.

- Data-driven insights and analytics facilitate informed decision-making, enabling organizations to respond quickly to market changes and make proactive adjustments.

- Agility and adaptability increase as organizations can rapidly assess operational data, identify trends, and adjust strategies and processes accordingly.

- IT-OT-ET convergence fosters collaboration and communication between different departments and teams within an organization.

- Shared access to integrated data and systems enables cross-functional collaboration, facilitating better coordination and knowledge sharing.

- Enhanced communication and visibility across IT, OT, and ET domains promote faster problem-solving, innovation, and improved decision-making.

- Convergence eliminates redundant systems, processes, and data silos, reducing duplication and minimizing operational costs.

- Centralized management of IT, OT, and ET systems leads to efficient resource allocation, optimized asset utilization, and reduced maintenance and support expenses.

- Predictive analytics and proactive maintenance capabilities enabled by convergence reduce downtime, extend equipment lifespan, and optimize resource planning.

- IT-OT-ET convergence strengthens safety and security measures through comprehensive monitoring, real-time alerts, and proactive risk management.

- Integration of security systems enables holistic threat detection and prevention.

- Compliance with industry regulations, data privacy, and cybersecurity standards is enhanced, minimizing legal and reputational risks.

- Convergence unlocks opportunities for innovation, enabling organizations to leverage emerging technologies, such as artificial intelligence (AI), IoT, and data analytics.

- Integration of ET into the IT-OT ecosystem fosters innovation in product design, manufacturing processes, and engineering practices.

- Convergence acts as a catalyst for digital transformation, enabling organizations to leverage technology advancements to drive competitive advantage.

League of Companies

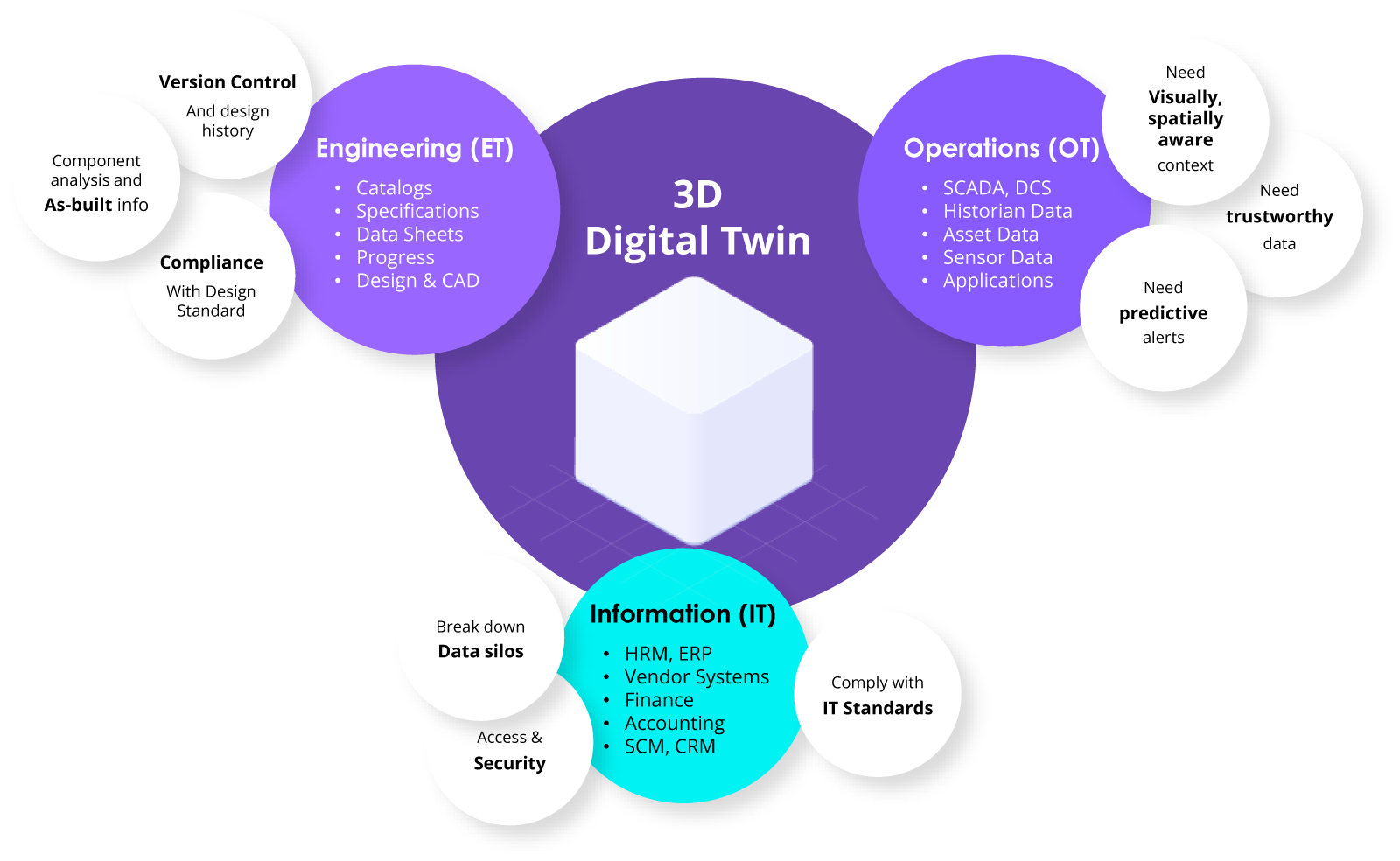

Digital Twins Accelerate IT-OT-ET Convergence

A digital twin approach can significantly expedite the transition to IT-OT-ET convergence by providing a virtual representation of physical assets, systems, and processes. This approach enables organizations to simulate, optimize, and validate integration scenarios, reducing the time and risks associated with physical implementations. Here’s a description of how a digital twin approach can accelerate the convergence process:

- Asset and System Modeling

- Integration Simulation

- Performance Optimization

- Predictive Analysis

- Training and Skills Development

- Risk Mitigation

- Continuous Improvement

- Scalability and Replication

- Create digital twins of physical assets, including machinery, equipment, and infrastructure, as well as IT and OT systems. Capture the relevant characteristics, functionalities, and data attributes of each asset and system within the digital twin.

- Use the digital twin to simulate the integration of IT, OT, and ET (Enterprise Technology) systems. Virtualize the interactions, data flows, and communication protocols between different systems and components, allowing for iterative testing and optimization of integration scenarios.

- Leverage the digital twin to analyze and optimize the performance of integrated IT-OT-ET systems. Simulate various operational scenarios, assess system behavior, and identify potential bottlenecks, inefficiencies, or conflicts early on. This enables proactive adjustments and optimizations to enhance system performance.

- Utilize the digital twin to conduct predictive analysis, leveraging historical data and real-time inputs. Predictive models within the digital twin can simulate the behavior of the integrated system, allowing for proactive identification of potential issues, failures, or anomalies. This enables organizations to implement predictive maintenance strategies and minimize disruptions.

Use the digital twin as a training tool for employees across IT, OT, and ET domains. Simulate real-world operational scenarios, providing a safe environment for employees to acquire hands-on experience and develop the necessary skills for managing the integrated systems effectively

- Employ the digital twin to assess and mitigate risks associated with IT-OT-ET convergence. Identify potential vulnerabilities, security risks, or performance gaps within the virtual environment, enabling organizations to implement proactive measures and security controls before actual deployment.

- Continuously update and enhance the digital twin as the convergence process evolves. Incorporate real-world data and feedback from the integrated systems to refine the digital twin’s accuracy and effectiveness. This allows organizations to implement ongoing optimizations and improvements to the integrated IT-OT-ET systems.

- Once a successful integration scenario is validated within the digital twin, it can be replicated and scaled across multiple assets or sites. This streamlines the deployment process, as the lessons learned and optimized integration strategies can be readily applied to similar instances.

League of Companies

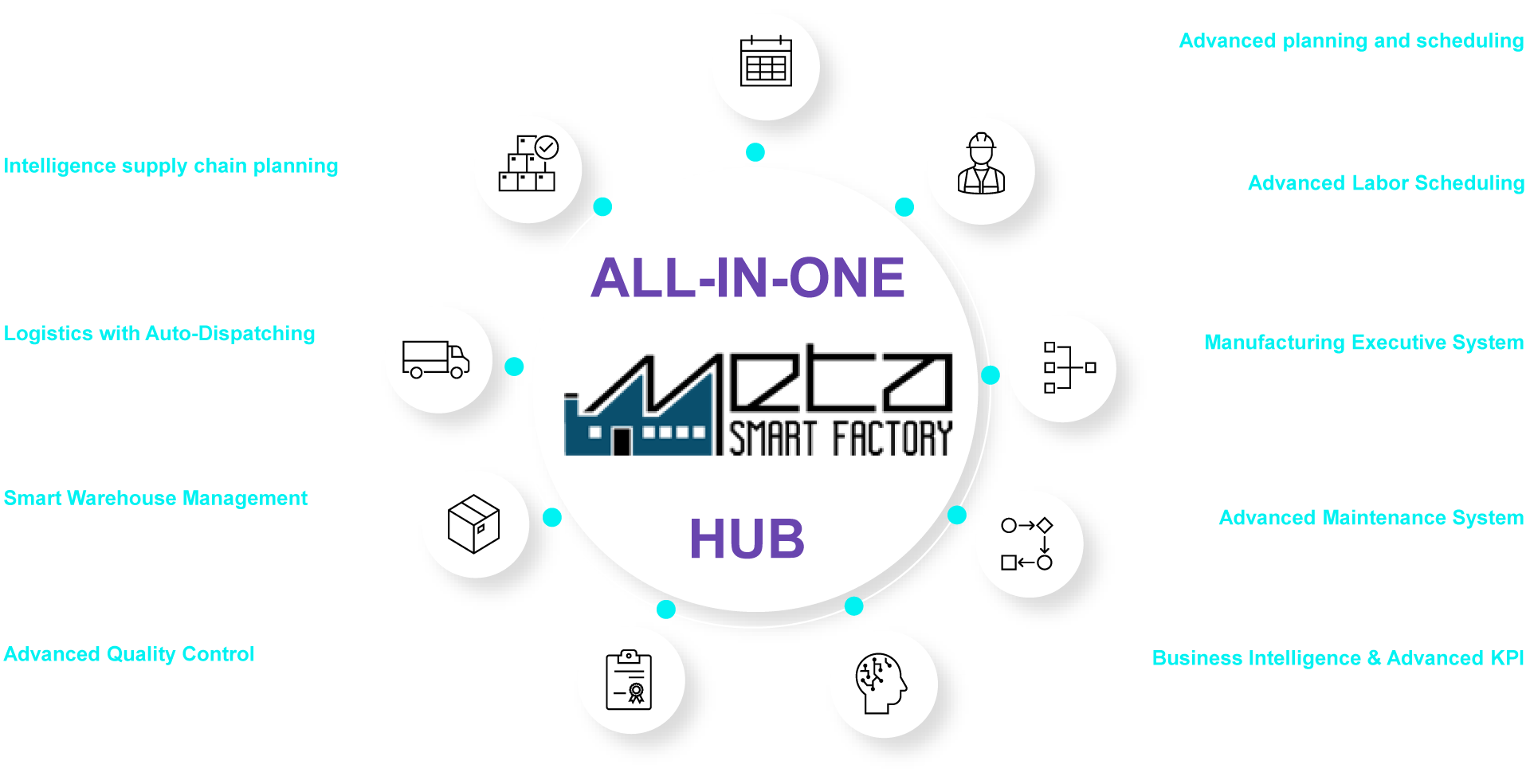

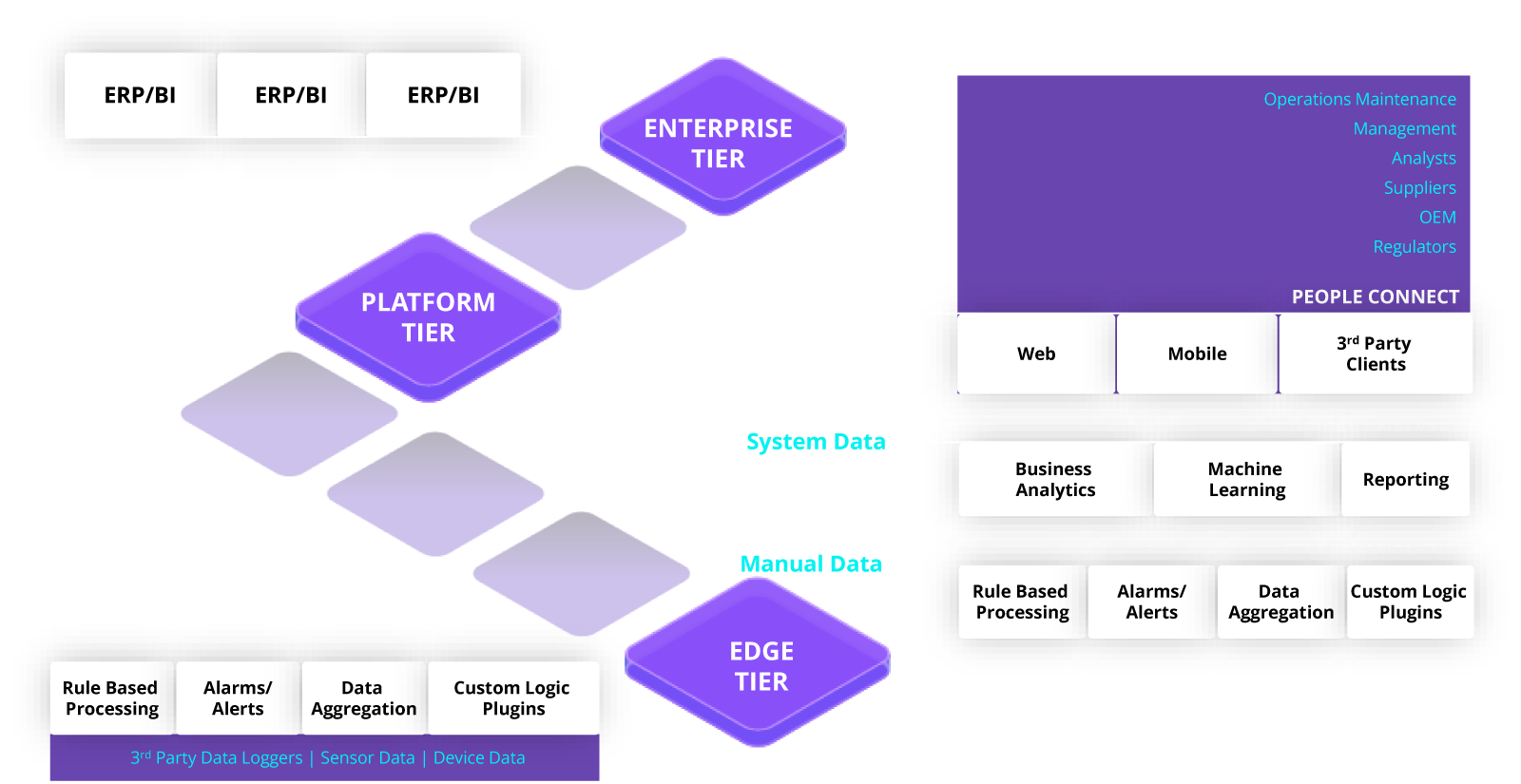

Smart Factory & Warehouse Solution

The League of Companies holds the esteemed position of representing Meta Smart Factory on a global scale and stands as the exclusive distributor for Meta Smart Factory across Africa. This comprehensive solution is a meticulously selected smart manufacturing software and hardware module designed to seamlessly fulfil each need of our clients. The integration of both hardware and software components is streamlined, while the system exhibits the adaptability to seamlessly integrate with diverse ERP systems, providing a comprehensive solution. Through the integration of SCADA, an intricate network of data extraction is facilitated from various sources, including PLCs and IoT devices, ultimately converging into a unified smart manufacturing solution.

League of Companies

Why work with us?

Manufacturing & IT Experience

Our Engineers have 25+ years experience at the highest level

One Price – Everything is included

We offer the solution as a SaaS model. Pricing is based on a monthly subscription model. License if per factory not per user.

Full lean & tailored solution

The solution can be customized and tailored to cover our clients needs – lean manufacturing solution

ERP Integration

During our POC integration will be free, local and well known (SAP, MS, Oracle IFS , SAGE etc)

Various Independent modules

You can choose between MES, APS, SCP, LS, MM, OC, WMS, BI. These modules can work independently

Data and Information Visibility

We harmoniously integrate diverse data sources, empowering informed decision-making and enhancing operational performance

SCADA Integration

Through the integration of SCADA, an intricate network of data extraction is facilitated from various sources, including PLCs and IoT devices, ultimately converging into a unified SMS

No Investment need, Fast ROI & Benefits

SaaS model, Increasing productivity, traceability, decreasing operational costs, process automation, decrease ERP license costs,

League of Companies

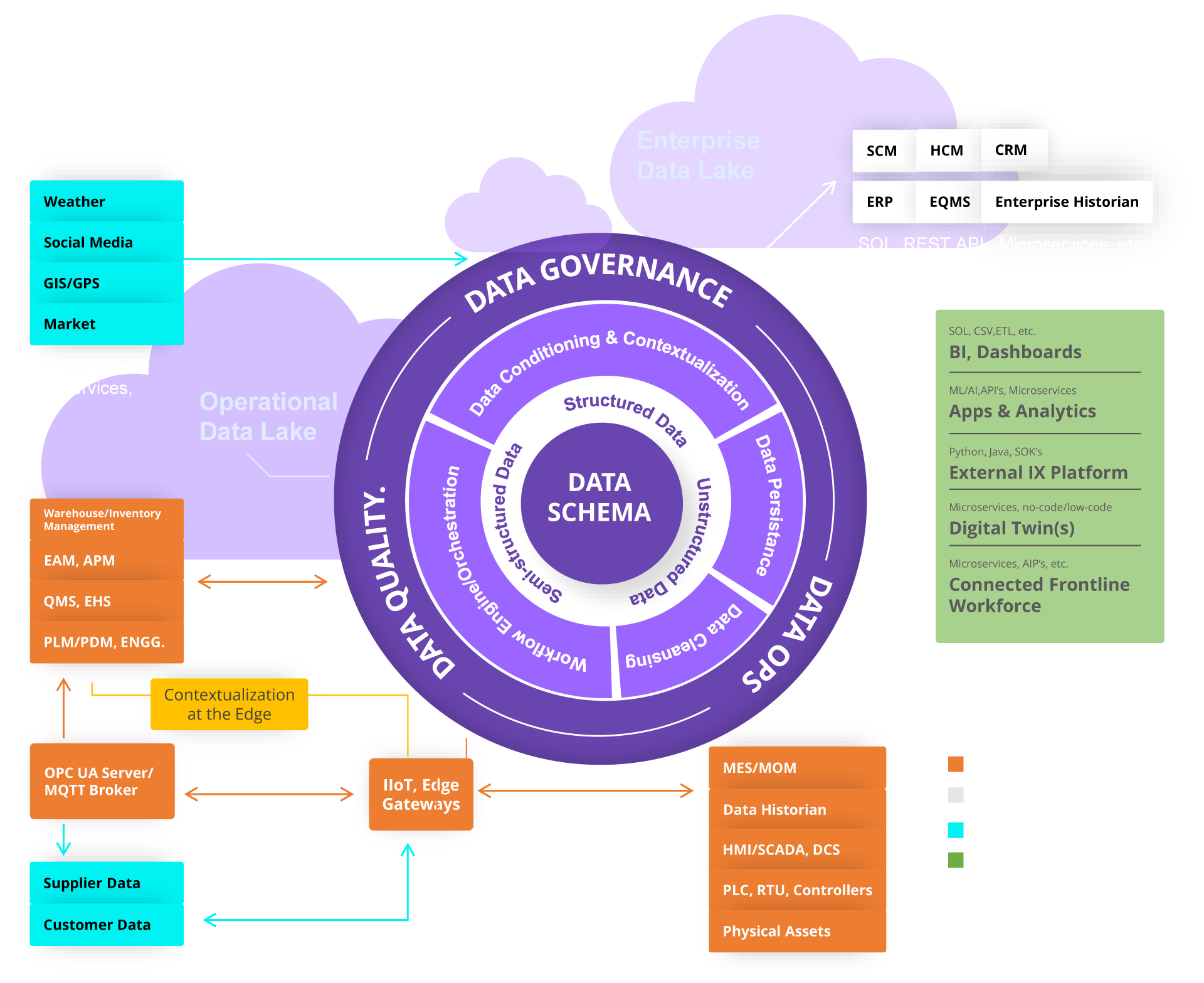

Industrial Analytics

The process of gathering, evaluating, and utilizing data from industrial activities is referred to as industrial analytics. It is similar to other types of advanced analytics in many aspects, but it is specialized to operational data and is used to create industrial value.

-

Performance Optimisation

Identify areas of optimization potentials to increase efficiency and productivity of the plant

-

Perscriptive Maintanence

With recommended actions, the operator can improve maintenance cycles based on condition, reduce spare parts costs and prolong the remaining useful life (RUL)

-

Energy Management

Based on the performance monitoring, it is possible to take data-driven measurements to reduce energy consumption and improve efficiency

League of Companies

Industrial Analytics Key Benefits and Features

Complete

Visibilty

By integrating all current data sources, we deliver comprehensive plant operations visibility.

Informed Decisions

Faster

Access to important insights, statistics, and analytics enables quicker and more effective decision-making.

Optimised

Operations

Give your subject experts and operators the capacity to optimize operations and increase profits.

Centralised Data Management

Data processing and storage are being centralized in order to standardize databases and datasets for real-time analysis.

Support Operator

Activities

Improved actionable insights help to understand events & manage them

Optimise Machinery

Health

Real-time data insights optimize processes & extend maintenance cycles

Increase

Efficiency

AI model-based optimization increases energy & production efficiency

Adaptable Analytics Solutions

We offer integrated AI/ML, ecosystem governance, real-time visualization, self-service analytics, and IT-OT integration.

League of Companies

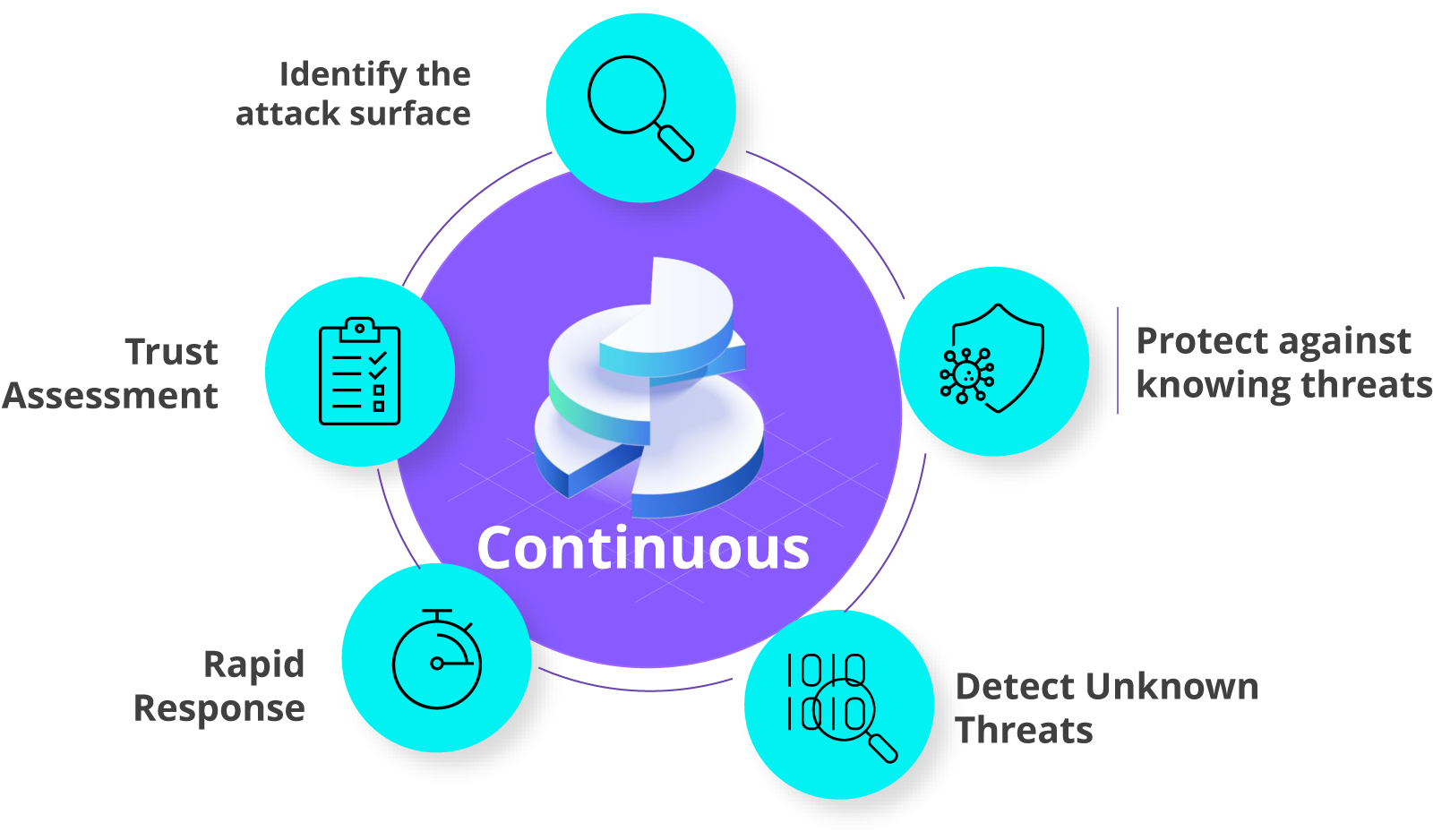

Operational Technology CyberSecurity

Companies must ensure that their operational and information technology security postures are prepared for the most sophisticated threats. To accomplish this, a cybersecurity system must cover the whole attack surface, integrate threat intelligence among security products, and automate threat responses.

This tutorial explains how Fortinet facilitates IT and OT integration while enhancing network security. It focuses on how OT and IT differ, why they are merging, and how to deal with increased risk. It highlights five best practices for protecting a converged environment and presents Fortinet cybersecurity solutions for OT and IT:

- Assess assets, classify them & prioritize their worth

- Network segmentation

- Examine traffic for potential threats and weaknesses

- Control user and device access

- Protect both wired and wireless access

For numerous reasons, integrating IT (Information Technology) and OT (Operating Technology) in the delivery of a corporate data management strategy is critical:

IT systems often deal with business-related data, whereas OT systems deal with operational data. Organizations can establish a holistic data management approach that includes both types of data by merging IT and OT. This connection provides a complete picture of the full data landscape, allowing for enhanced decision-making and operational efficiency.

- Insights from Real-Time Data

- Improved Data Quality and Accuracy

- Enhanced Operational Visibility

- Effective Cross-Domain Collaboration

- Security and risk management

- Scalability and Future Readiness

OT systems collect real-time data from sensors, devices, and machinery on the shop floor or in industrial environments. By integrating real-time data with IT systems, firms can acquire rapid insights and make data-driven choices more quickly. It enables the detection of anomalies, predictive maintenance, and real-time operation optimization.

Organizations can build data synchronization mechanisms, data validation processes, and data cleansing strategies by connecting IT and OT systems. This integration contributes to the accuracy, consistency, and dependability of data created in OT systems when transported and processed in IT systems. It lowers the likelihood of data inaccuracies, inconsistencies, and duplication, hence enhancing overall data quality.

By combining IT and OT data, enterprises can have a unified perspective of their operations. It enables integrated monitoring and reporting on both business and operational indicators. This visibility enables firms to detect correlations, trends, and patterns that could have gone unnoticed if IT and OT data were analyzed independently. It promotes greater operational insights and proactive decision-making.

IT and OT teams may have separate roles, responsibilities, and skill sets. Integrating IT and OT data encourages collaboration and knowledge sharing among these groups. Cross-domain analysis, problem resolution, and invention are all possible. IT and OT experts can collaborate to establish more effective data management strategies, streamline processes, and drive digital transformation projects.

Problems are also addressed by integrating IT and OT data management. Targeted attacks on OT systems, such as those operating vital infrastructure, are common. Organizations may create a complete security framework that protects both IT and OT assets by integrating IT and OT security measures. It guarantees that access restrictions, threat detection, incident response, and compliance are consistent throughout the whole data ecosystem.

Integrating IT and OT data management positions firms for future development and scalability. As data volumes and complexity grow, a unified approach enables greater scalability and flexibility. It allows for seamless integration with developing technologies such as artificial intelligence, machine learning, and edge computing, which are becoming increasingly important in both the IT and OT sectors.

In conclusion, integrating IT and OT in the delivery of an enterprise data management strategy allows firms to capitalize on the synergies that exist between these areas. It provides complete data management, real-time insights, improved data quality, increased operational visibility, effective collaboration, strong security, and future readiness. Organizations can access the full potential of their data and effectively drive digital transformation programs by breaking down silos between IT and OT.

League of Companies

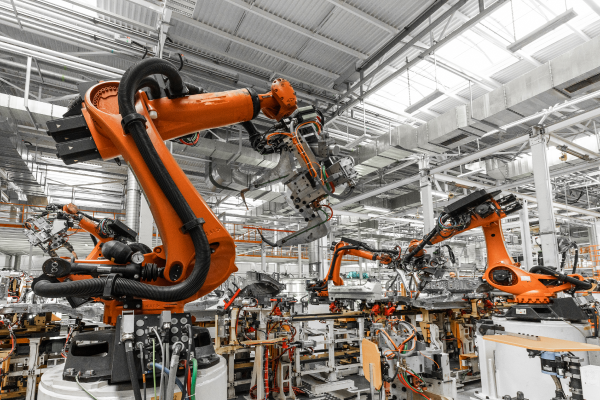

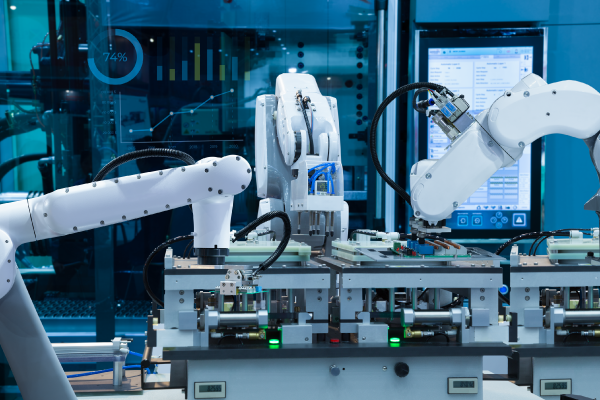

LOC's Integration With Smart Engineering In Industry Implemetations

Prototype Development with Industrialisation

Semi-Automated/Automated Production Lines

Inventory Management & Supply-Chain

Smart Planning For Manual Assembly Lines

PLC Programming

& Automation

Automation in CNC Equipment & Manufacture

Members

Download Our Company Profile

Your journey to an extraordinary tomorrow starts here.

Tell us a little bit more about yourself and what your company needs right now. We’ve got ideas, inspiration and success stories that can help!

- info@leagueofcompanies.com